SELECTION OF COLD STORAGE PANEL

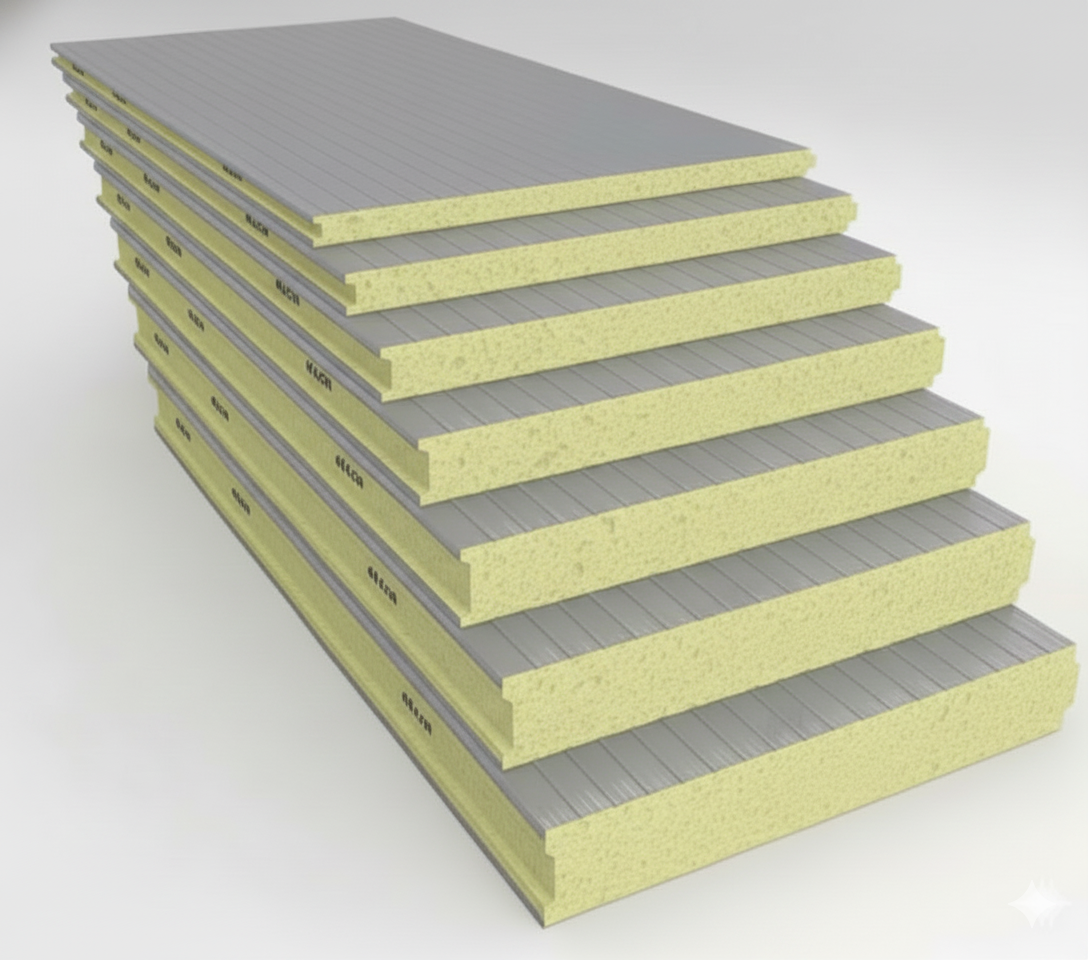

Polyurethane panel with the variety of available external plating (SII, PVC-coated steel,Stainless steel) guarantees the heat insulation performance of cold storage.This helps maintain the desired storage temperature despite the huge difference between the internal and external environment,ensuring equipment working efficiency,making it energy-saving in the long run.

Panels made of polyurethane (PU) are strong but lightweight. Depending on their thickness, PU panels can sustain extremely cold temperatures.

ADVANTAGES OF POLYURETHANE INSULATED PANELS

Polyurethane offers great structural strenght per length

Offers a great R value to expanded polysterene per thickness.

Excellent insulating efficiency over a wide temperature range.

When heated or melted, polyurethane does not melt.

Polyurethane does not cause flames to spread within a fire or increase the intensity of an existing fire.

Moisture resistance and water repellent.

CUSTOMIZED COLD STORAGE PANEL

Specification for Customized PU Panel

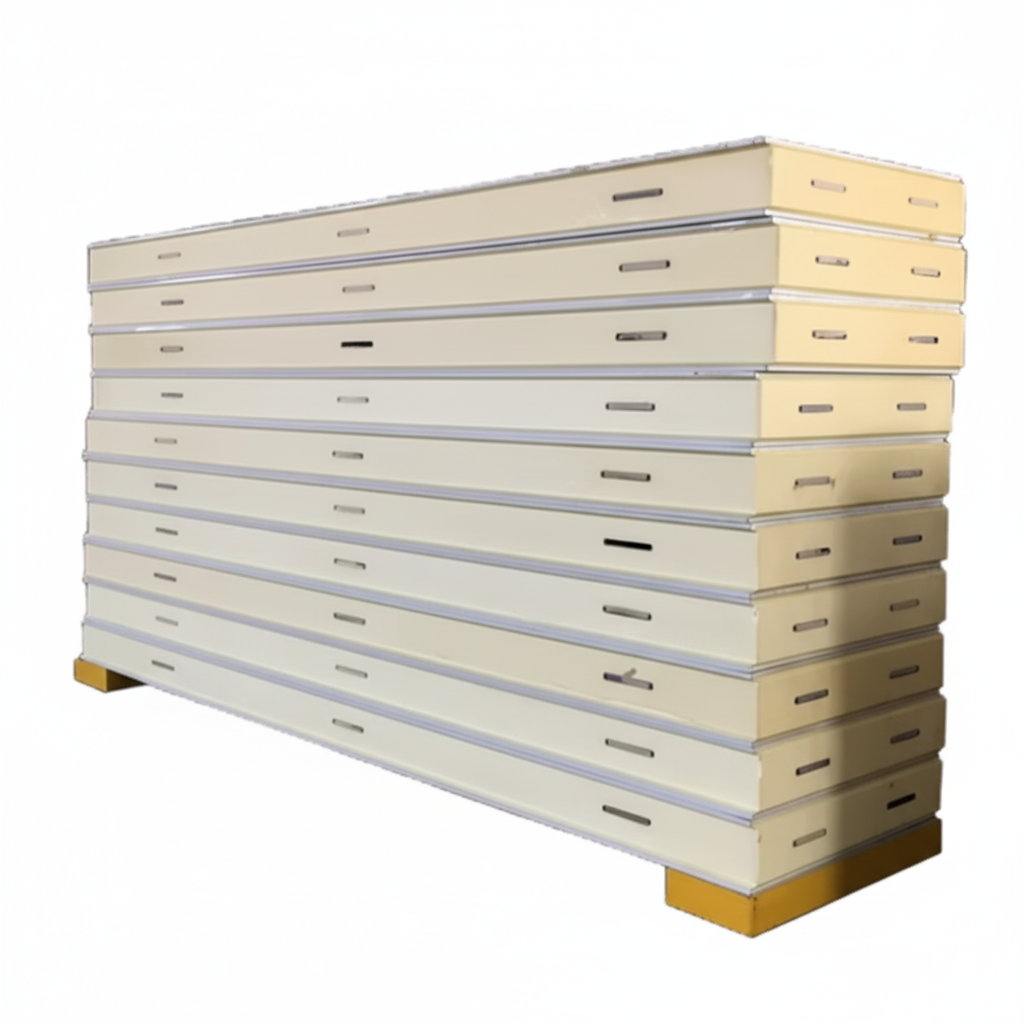

PU panel standard width is 1.00m , with height ranging from 1.50mH to 11.50mH. PU panels can be tailored according to client’s requirement.

Features a designated camlock system attachment to ensure panels are attached securely.

Sandwich panels are composed of two exterior layers of pre-painted, 0.5mm steel with a polyurethane core that insulates the panel from heat and sound.

Polyurethane panel thickness offered are the following:

AUTOMATIC POLYURETHANE (PU) PANELS

Automatic, continuous production lines that integrate multiple pieces of technology enable the efficient and large-scale manufacturing of sandwich PU panels. These lines automate the process of forming, uncoiling, and precisely dispensing and foaming a polyurethane (PU) core. The completed panel is then heated, pressed, and cut to size. Thermal insulation, structural longevity, and constant product quality are guaranteed by this high level of automation.

Polyurethane panel thickness offered are the following:

FREEZETECH PIR and PUR Core Characteristics Comparison Table

Feature

Fire Performance

Thermal Insulati on Efficiency

Dimensional Stability

Mechanical Strength

PIR

Excellent

Hard to ignite(B1)

Forms a dense,protective char layer upon fire exposure,effectively resisting flame spread and high-temperature penetration

Superior

Lower long-term thermal conductivity(typically≤0.022 W/m.k).

Provides more durable and stable insulation,leading to better energy savings over time

Advanced

More stable molecular structure,wider temperature tolerance range.

Less prone to shrinkage or deformation due to temperature fluctuations,maintaining panel integrity long-term and preventing thermal bridges.

Maximum Strenght

At the same density, PIR foam generally has higher compressive and bending strength than PUR.

Results in a more rigid and durable panel.

PUR

GOOD

Hard to ignite(B2)

Has good flame retardancy,but its charring ability and fire resistance are inferior to PIR

Exceptional

Excellent insulation properties(thermal conductivity typically ≤0.023-0.026W/m.k).

A traditionally high-performance insulating material

Quality

Offers good dimensional stability.

However,long-term stability under extreme cyclic temperatures is slightly lower than PIR

Up to satisfactory

Mechanical strength is sufficient for the vast majority of cold storage applications.

Color - Steel Plate Thickness

Color steel plate thickness

0.40 / 0.50 / 0.60

Foundation plate

ZI(100%)

ZA(Z90%+A10%)

AZ100(A10%+Z90%)

AZM150(A10%+Z90%)

Stainless Steel

Coating type

PE

SMP

HDP

PVDF

Maximize Impact. Minimize Effort.

Instantly elevate your cold storage or facility with Freezetech Dynamics' next-generation polyurethane panels. Achieve a premium, high-impact finish without the outrageous cost or complex downtime of traditional builds. Our panels deliver zero maintenance, unmatched moisture protection, and incredible durability—all with feather-light weight and lightning-fast installation. Stop settling for less; upgrade to superior performance and speed today.